I’ve discussed the many ways the different phases can be arranged in some standard(ish) management contexts, and how the work in each phase can be broken down in multiple dimensions, but those hardly exhaust their possible arrangements. Another important source of variation has to do with work performed in getting a project in-house to begin with. It doesn’t apply in every case, and especially doesn’t typically apply for work done for internal customers, but there are a lot of possibilities when it does. I hope the following example will illustrate the idea.

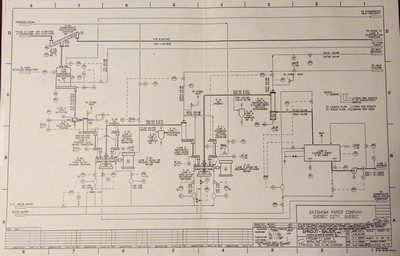

In my first engineering job, as a process engineer for a company that made capital equipment and turnkey thermo-mechanical pulping lines for the paper industry, about half my job involved creating process and instrumentation diagrams (P&IDs) that supported the negotiations our senior engineers and sales staff would have with potential customers. The drawings would include the heat and material balances showing the amount of materials the system would have to process to generate the customers’ desired output, and the conditions in each part of the process. The types of equipment in each system were chosen to produce the desired paper characteristics. The sizing part was fairly straightforward, but the quality part seemed to be as much art as science, and was driven more by experience than by prediction from first principles. This would allow the next group of designers to specify the size and quantity of the equipment that would need to be included in the system, so that prices could be attached and a bid prepared.

The process of creating each set of drawings took several iterations between me and the drafting department, and then there could be several rounds of modifying the drawings as the design and configuration of the proposed system evolved. I remember going to one plant that was actually built from drawings I did (Daishawa, Quebec City) and also doing multiple rounds of drawings for a plant in the Orinoco River region of Venezuela. I don’t know if that plant ever got built, or if so who built it. I remember that it included huge storage tanks (often called chests) that the energy-intensive pulping line(s) would fill up overnight when electricity was cheap (they called this load shedding), and which would be drawn down during the day as the actual paper machine ran continuously.

So the customer identified the requirements, a first pass at the conceptual model and design work was completed, and then and only then could the implementation begin, if our company’s bid was the winner. Once a project was actually undertaken, there would then be another round of requirements, design, and conceptual modeling activities to work out specific details of the system, equipment layouts, and so on. One can think of the sales effort as one independent project, with the submitted bid representing the work of the implementation and test phases, and the construction of the actual production line and all its equipment as another independent project, or one can think of the entirety of the work as being a single project with some unique patterns of iteration.

In the end it doesn’t actually matter. What matters is being able to recognize the correct activities to perform in each phase and what phase you are likely to be in at any given time. I know the IIBA sets great store on not being prescriptive. I think the many possible configurations of phases show that my framework is extremely flexible, and that anyone who thinks it is overly prescriptive probably doesn’t understand it yet.