The vast majority of my career has involved process analysis and process modeling, usually but not always associated with computer simulation for various applications. I’ve always thought of the two activities as being essentially the same, but the BABOK distinguishes the two terms by defining modeling as the creation and maintenance of models, which are representations of the processes of interest, and defining analysis as what you do to design or improve a process. I think of them as being completely intertwined because you cannot do process analysis without having a process model, and there’s not much point in having a model if you aren’t going to use it to perform analysis.

Note that the BABOK spells “modelling” with two Ls per rules in used all English-speaking countries except the United States. The IIBA, of course, is based in Canada. We Americans are a bit iconoclastic on this point.

While modeling and analysis are largely intertwined, I can think of a few legitimate reasons for maintaining models without doing subsequent analysis.

- Documentation

- Communication (for common understanding and situational awareness)

- Configuration Management

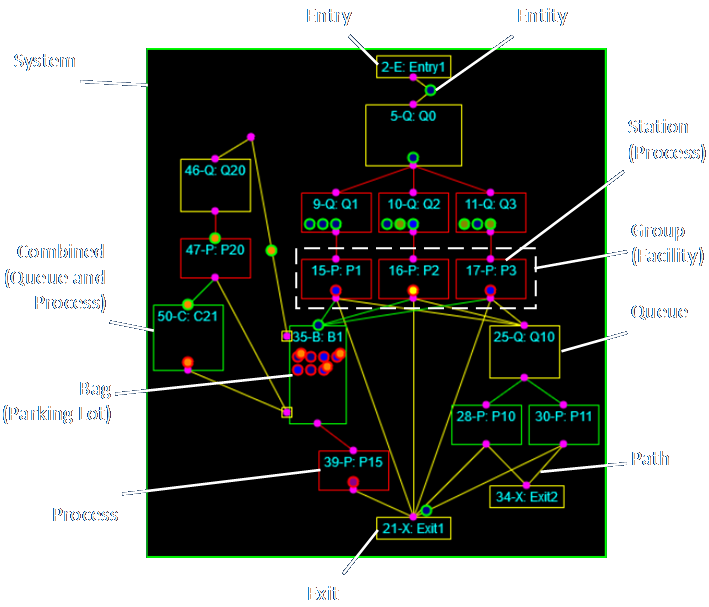

Models come in many forms. I typically think about them as having the following components:

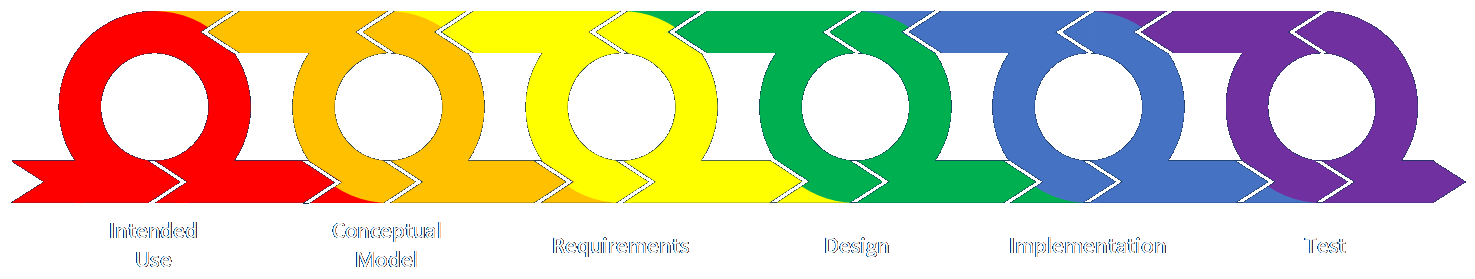

Within my analytical framework, process modeling is the process of creating or updating the conceptual model of the process under consideration. This is the second of the six major phases of a project or engagement. You perform discovery to find out what materials and operations make up the process, and then you perform data collection to characterize each aspect of the process, both qualitatively and quantitatively.

Analysis is typically done during the requirements and design phases of an engagement. These are phases three and four in my framework. The number of techniques that can be used to perform analysis are practically infinite. Simulation is a tool I use quite often. Six Sigma is about reducing variation to (in theory) reduce waste and improve quality. Lean is about rearranging or substituting steps to accomplish more work with the same resources or the same work with less resource &emdash; or ideally both.

I don’t know how much of the material from the BABOK I’m allowed to reproduce here, so I will instead refer readers to section 10.34 for its description of Process Analysis and section 10.35 for its description of Process Modeling. These are within chapter Ten’s list of fifty business analysis techniques.