Introduction 01: Overview

R.P. Churchill, CBAP, PMP, CSPO, CSM, CSD

Introduction 01: Overview

What do we think about when creating solutions?

There are many reasons to begin projects, and many different things to think about. Very few people, unless they have seen a lot of different things over a long period of time, will be aware of all or even many of these. That said, when they are described, they should all fairly obvious.

The context for these discussions involves organizations that either have or are looking to build repeatable, consistent, reasonably high volume business processes. That said, many of these ideas can be applied to creating and modifying products.

Few small or medium-size organizations are likely to understand these approaches and considerations. Potential customers may jump to what they know about some specific method or technology. The intent of these quick hits is to help all practitioners and organizations understand the full range of methods available, and situations and contexts that should be considered. Alternatively, they may assume that sulutions can be implemented quickly without significant, up-front analysis.

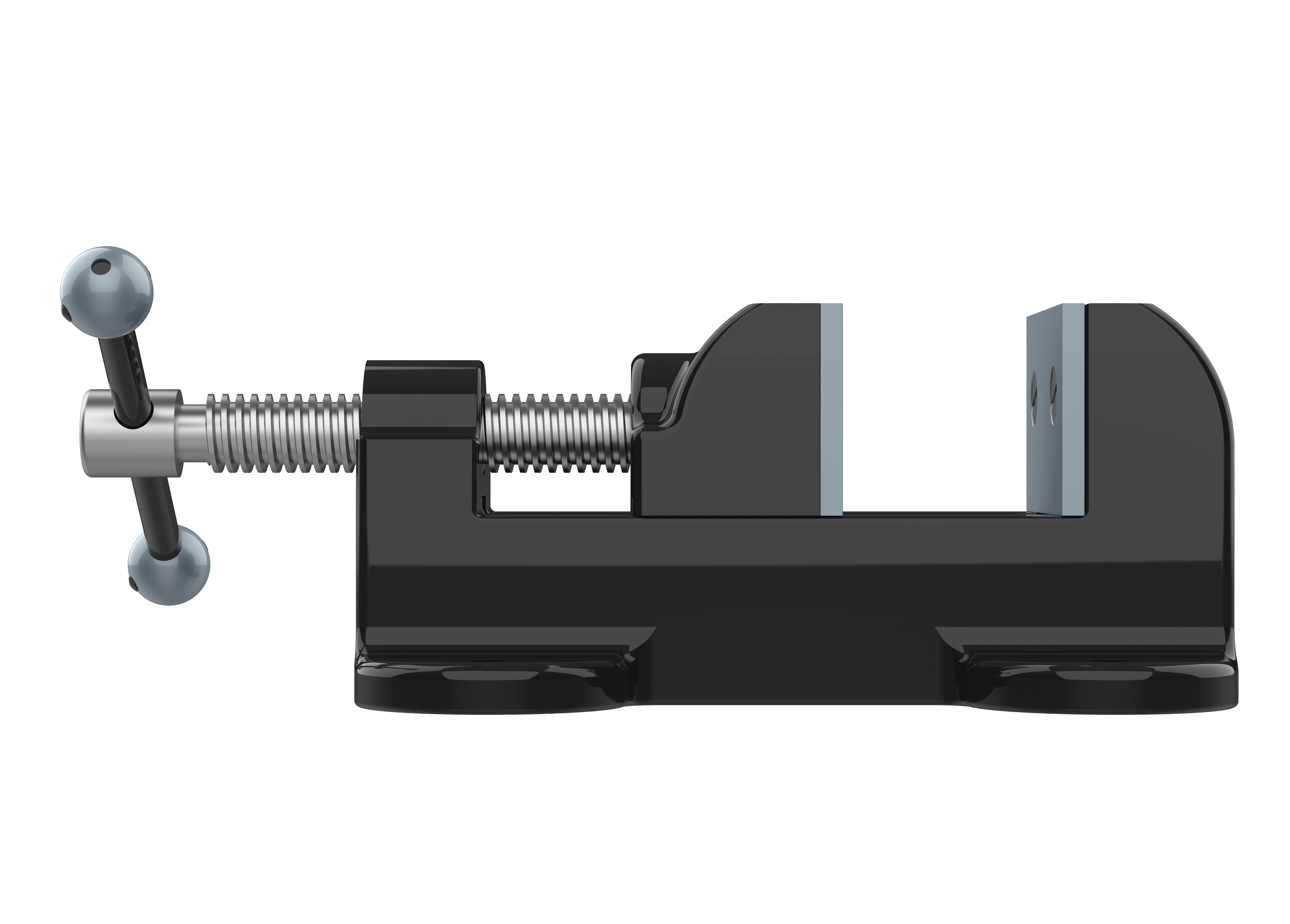

If you think of all these approaches as individual tools, you'll see that most teams, whether they are internal to an organization or external as a vendor or consultant, tend to use only a small subset of the tools available.

So let's review the entire toolbox!

Introduction 01: Overview

What do we think about when creating solutions? (cont'd)

Sometimes, a solution is pretty obvious, and then it's just a question of executing it. But not every problem can be solved the same way.

One or two of the following considerations may be the main drivers, but several others may also come into play during a given engagement.

Different organizations (including departments within organizations) may be driven by different approaches.

Some of these approaches may overlap or otherwise appear very similar to each other. I would love to hear your thoughts on how the list might be improved.

Link to detailed discussion.

Introduction 01: Overview

Important Context

The Introduction pieces give a background of the entire set of approaches and considerations and also explain the basics of how I conduct engagements where I am able to use any or all of the tools I discuss.

The Approaches are a mix of internal actions you initiate to build or improve a business process and external events that may cause you to build or modify a business process in response.

The Considerations dichotomies you may need to think about as you are working through an engagement and applying one or more of the approaches.

Introduction 01: Overview

Examples of Benefits Realized

The following items come from near the top of the landing page for my website:

- Automation saved 10% on fuel costs for gas-fired steel reheat furnaces and saved 30% on personnel costs for a disability insurance underwriting department.

- Moving implementations to lower-cost and more readily available hardware and software platforms saved up to 70% on procurement costs and improved maintainability and standardization.

- Thorough discovery and data collection efforts led to accurate simulation of systems for sizing, process improvement, and design; accurate and effective troubleshooting; and complete, robust solution designs.

- Effective system decomposition led to modular, flexible, understandable, robust, maintainable solutions.

- Developing custom tools for ongoing budget oversight led to effective predictive and Earned Value management of projects and programs.

- Powerful user interface designs gave users effective and accurate control of systems.

- Detailed and creative graphic displays and animations provided users with enhanced understanding and situational awareness.

- In-depth technical experience and a willingness to help others has led to successful onboarding, training, mentoring, and support of numerous individuals in many environments.

- Reverse-engineering led to effective and cost-efficient maintenance of existing software systems and understanding needed to implement modernized replacements.

- Application of efficient numerical methods for engineering calculations led to faster systems that could offer advanced calculations for real-time training and industrial control.

- Analysis and conditioning of large data sets allowed them to be used as inputs and effectively interpreted as outputs for detailed tradespace studies and other applications.

- Site operational audits showed that contractual production volume and quality requirements were being met.

- A wide range of test, verification, validation, and acceptance and accreditation methods demonstrated that software systems were implemented correctly and could be safely and effectively employed for their intended use.

Introduction 01: Overview

Continuous Improvement

All of these tools and considerations are applied continually.

Making one thing better may move the bottleneck to a new place. This means you should be mindful of the Theory of Constraints. The Five Focusing Steps are:

- Identify the constraint

- Exploit the constraint

- Subordinate the constraint

- Elevate the constraint

- If the constraint is "broken" go back to step 1

Introduction 01: Overview

Continuous Improvement

When does this process end?

Never!

BUT... each potential improvement needs to be weighed against the cost and disruption of retraining, employee comfort, and so on.

Introduction 01: Overview

Next: Introduction 02: Who Am I and How Do I Work?

Index

| Introduction | ||

|

|

||

| Approaches | ||

|

|

||

| Considerations | ||

|

|