Thermo-Hydraulic and Thermodynamic Simulations

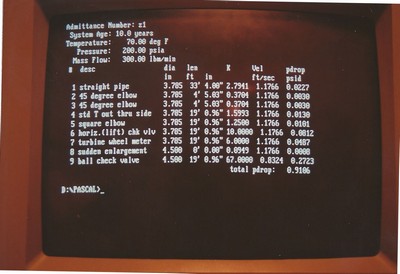

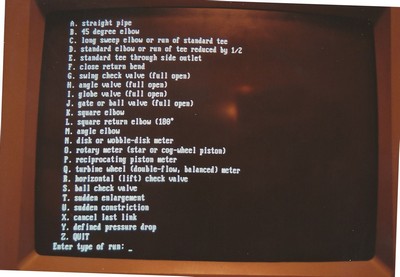

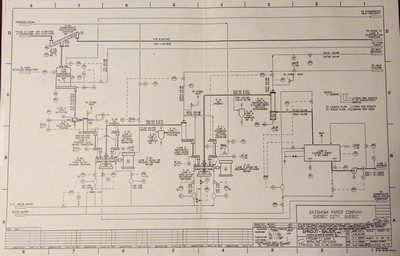

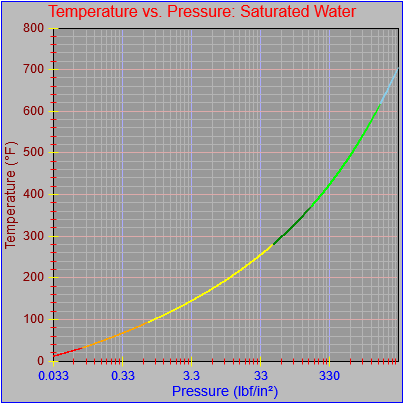

I started out as a mechanical engineer and my first job was as a process engineer in the paper industry. Along with having the learn the highly empirical tradecraft associated with pulp quality I also did a lot of thermodynamic calculations as part of heat and material balances used for system design and sizing. I did a lot of calculations by hand but also built tools to calculate the properties of steam and pressure drops as a function of flows through various kinds of equipment. Somewhere during that time I wrote a TSR (terminate-and-stay-resident) utility I used to allow designers to do steam table lookups.

The animation at the top of this page shows how the temperatures in a cross-section of a square billet change over time as it is heated prior to being rolled into a final shape. It involves solving a series of simultaneous, linearized, differential equations for temperature while considering the energy flows, dimensions, and material properties of the steel. The calculations include terms for thermal radiation, thermal conductivity, and thermal capacity (the latter two of which change continuously with temperature). The same techniques are used to calculate pressure-flow solutions for networks of fluid flows as well, as well at solutions for transport properties like heat, radiation, and material concentrations. Control systems I updated and designed for induction melting furnaces and thin strip galvanizing lines also included calculations for inductive heat transfer. The latter work led to a patent for an insight into simplified control methodology.

I also used a program called GEMS (General Energy and Material Balance System, which appears to no longer have a presence). It was very useful but I didn't quite know how it worked -- until I took my next job writing simulations for nuclear power plants. At that point I recreated most of the tool on my own and came to understand it at a fairly deep level.

Over the course of jobs in the paper, nuclear, and steel industries I got a career's worth of education about continuous simulation in general and thermodynamics and fluid mechanics in particular, along with a lot of experience in numerical methods (and software engineering... and computer graphics...).